Tamas Pump Audits; The Simple Solution

The industrial sector is the largest employer of pumps, but most other building types, from hotels to hospitals to private homes, also depend on them for comfort and sanitation.

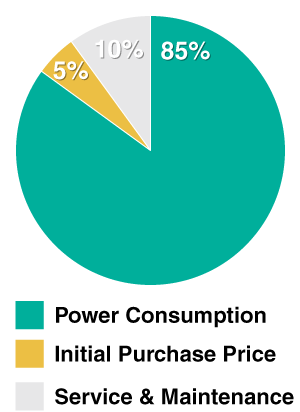

Pump Audits show that up to 60% of the energy consumed by pumps could be saved. In other words, there is a significant potential for saving money if your old pumps are replaced with new efficient pumps. With rising energy prices, it makes sense to get a professional check-up and to see how fast a new investment may pay back with a new Tamas pump package installed.

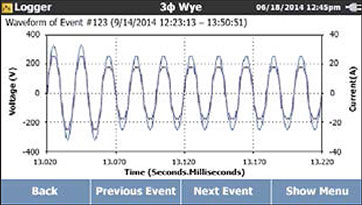

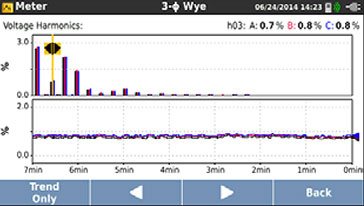

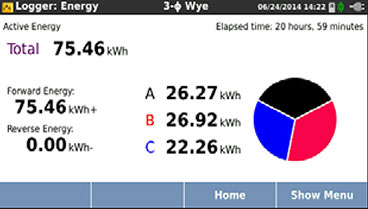

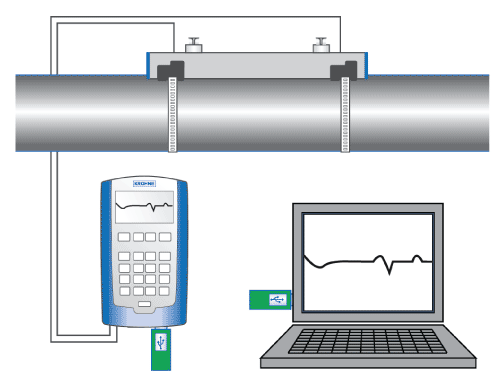

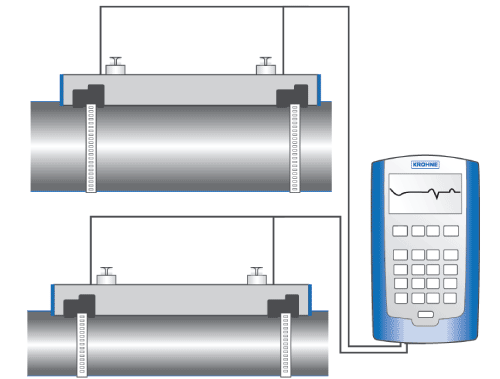

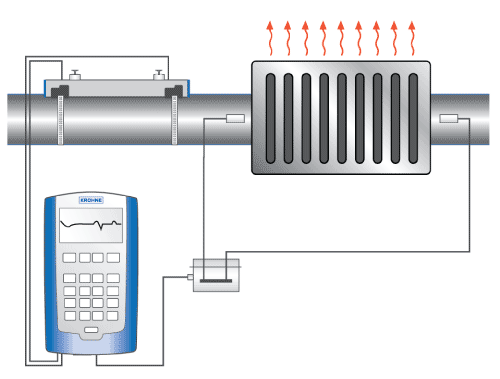

A Pump audit is performed by our specialists based on measurements. It focuses on the amount of material the pump is handling and flow variations during a relatively short and well-defined period. The audit assesses the overall efficiency of your pumps and proposes changes to be made to improve efficiency. The proposals are supported by calculations of the savings to be made, the reduction in CO2 emissions, and the payback time on any investment.

The benefits are operational cost savings and not least a significant reductions to installation carbon footprint.

What is a Pump Energy Audit?

A Pump Energy Audit gathers information that highlights areas where pumps and pumping systems may not be operating at optimum efficiency, as well as highlighting areas for improvement.

Why Get a Pump Energy Audit?

By undertaking a Pump Energy Audit, we will provide you with a report that recommends ways to improve pump efficiency and quotes for the remedial work, as well as calculating the payback period for any new equipment or repairs.

View Service Brochure

Custom, Reliable Hydronic Systems

Custom, Reliable Hydronic Systems